Ergonomics Laboratory

The Ergonomics Laboratory provides a comprehensive environment for the in-depth study of human performance and its interaction with systems, products, and workplaces. Our facility is designed to support both foundational research and applied industrial projects, with a focus on enhancing human well-being and productivity.

Core instrumentation includes:

- Data Acquisition System: Two multi-channel Biometrics DataLogger and Analysis Software form the core of our lab, allowing for synchronized capture and detailed examination of various physiological signals.

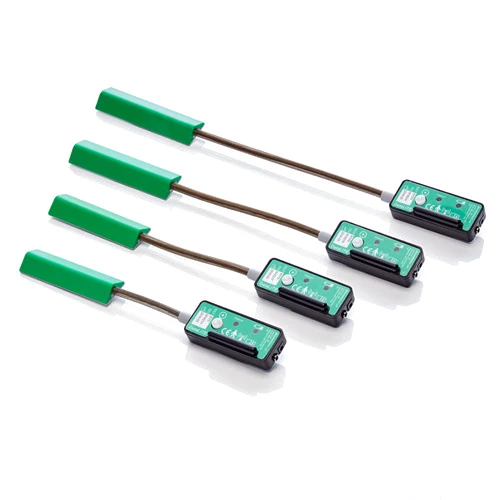

- Kinesiological & Muscle Analysis: We utilize Surface Electromyography (EMG) Sensors to quantify muscle exertion, as well as Goniometers and Torsiometers to precisely measure the range of motion and angles of body joints.

- Force Measurement: To assess physical strength and task demands, the lab is equipped with Hand Grip Dynamometers, Pinchmeters, Myometers, and a versatile S-beam Load Cell that can be adapted to a wide range of applications.

These tools enable students and researchers to conduct comprehensive ergonomic assessments, evaluate manual handling tasks, analyze user interface designs, and develop solutions to minimize the risk of work-related musculoskeletal disorders.

DataLOG

DataLOG and Analysis Software

Goniometers

Torsiometers

EMG Sensor

Myometer

Hand Grip Dynamometer

Pinchmeter

S-beam Load Cell

Contact Switch

CAM & Robotics Laboratory

The Computer-Aided Manufacturing (CAM) and Robotics Laboratory is a state-of-the-art facility dedicated to providing practical education and research opportunities in Industry 4.0 technologies. The lab empowers students to design, manufacture, and automate complex systems, from a single component to a complete production line.

Key equipment and capabilities include:

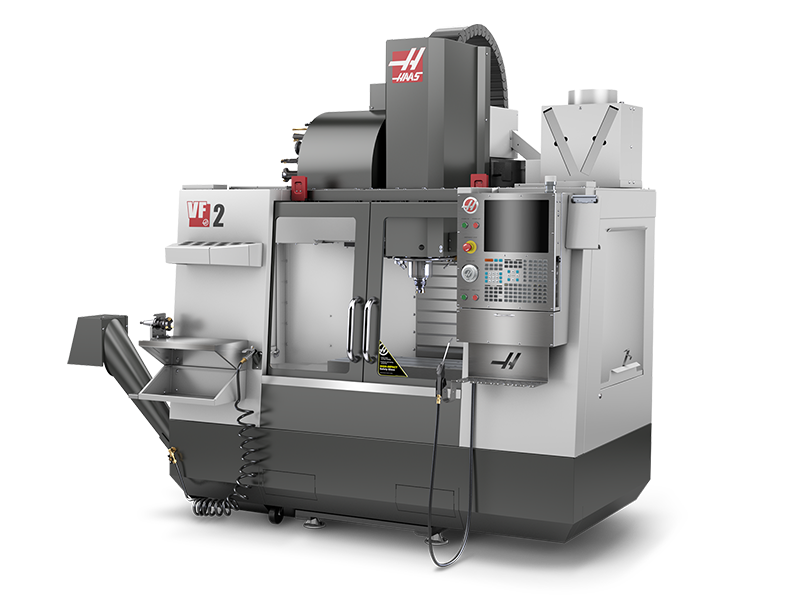

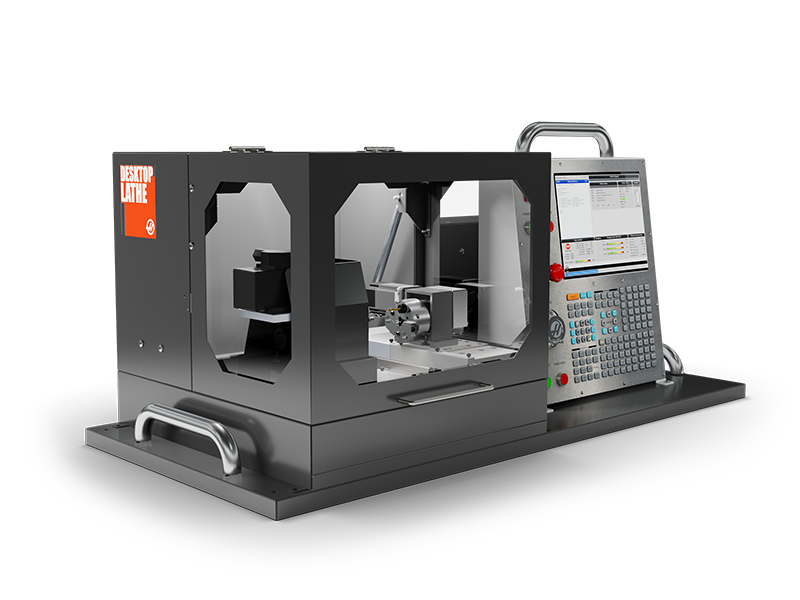

- CNC Machining: At the core of our manufacturing capabilities are industrial-grade machines for high-precision subtractive manufacturing. This consists of a Haas VF-2 CNC Milling Machine for complex 3-axis machining and a versatile Haas Desktop CNC Lathe for turning operations.

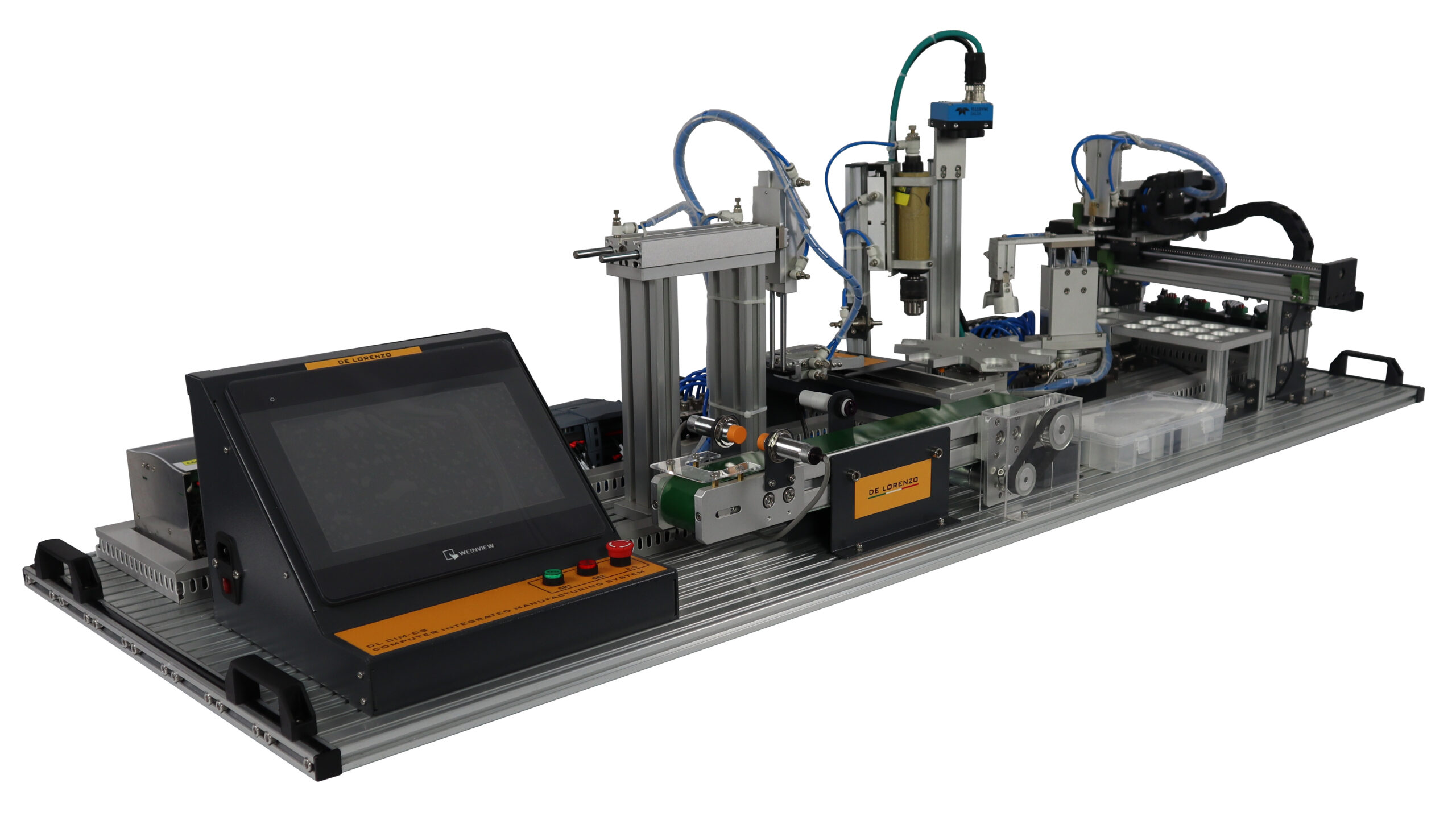

- Industrial Automation and Control: Students gain hands-on experience with industry-standard automation hardware. The lab features a Schneider PLC (TM221) system with analog, temperature, and VFD modules controlled via a Harmony HMI. Additionally, a comprehensive De Lorenzo DL CIM-CS system, powered by a Siemens S7-1200 series PLC with Weintek Weinview HMI, enables integrated manufacturing research, including a machine vision system for quality control and a SCADA platform for process supervision. A variety of industrial sensors (inductive, capacitive, photo) are available for building and troubleshooting automated tasks.

- Rapid Prototyping: For additive manufacturing and quick design iteration, the lab is equipped with a Creality CR-10 Smart Pro 3D printer, enabling the fabrication of custom parts, fixtures, and functional prototypes.

- Embedded Systems: Foundational control logic and custom robotics projects are facilitated using Arduino microcontrollers and Raspberry Pi to provide a flexible platform for integrating sensors and developing unique automated solutions.

This integrated suite of equipment allows students and researchers to tackle real-world challenges in manufacturing, process control, robotics, and mechatronics.

Haas VF-2 CNC Milling Machine

Haas Desktop CNC Lathe

Creality CR-10 Smart Pro 3D Printer

Schneider PLC System

De Lorenzo DL CIM-CS System

Siemens SIMATIC S7-1200 PLC